15's patents, 13 filings and 6 patent filings have been extended over 15's years to invest more than 80 million dollars by Intel, Motorola, Energizer, the United States Navy, and the Argonne National Laboratory / Energy Department of the United States States developed. Among other things, grants from the Department of Prefabrication and Novellus Systems flowed. XNRGI technologies enable scalable mass production at the lowest cost in the industry, using the semiconductor wafer and contract manufacturing perfected in the last 20 years in Silicon Valley. This combination of original technologies and proven manufacturing techniques gives XNRGI an unparalleled manufacturing scale and low cost with minimal investment.

A new architecture for storable power

The problem

Energy density in batteries is the primary bottleneck for the worldwide proliferation of electric vehicles and renewable energies (such as solar and wind power). Today's batteries have a short life, are too expensive, too big and too heavy, so they limit a variety of applications. Batteries often require specialized manufacturing equipment for a variety of applications, which limits the ability to cost-effectively scale production and generate enough power to meet the global need for stored energy.

The global annual production capacity for battery technology is currently 150 gigawatts. According to the IPCC (Intergovernmental Panel on Climate Control), the global demand for renewable energies for the World Wide Web alone will amount to 2050 terawatts by 42. In addition, several terawatts are required for the transport and electrification of other emerging countries. And that amount of energy will not come off the grid because, according to Lawrence Livermore Labs, 68% of all energy put on the US grid is "wasted" through resistance, transmission, transmission, and restriction (energy that is rejected) if it cannot be used or stored as the mains is not a battery).

Clearly, there is an overwhelming need to find a cost-efficient, scalable battery manufacturing architecture that accommodates improvements in density, size, weight, and shape for every application, including transportation, networking, consumer electronics, and the Internet. In addition, this architecture would have to facilitate the mass production of batteries that is safe, tunable and affordable.

Such an application could enable renewable energies to cope with the exponential global growth in stored energy.

The solution

XNRGI with its new stored energy architecture is the solution. It is the only technology that can scale battery production to terawatt capacity using existing battery manufacturing infrastructure. All other battery technologies require extremely high levels of investment and several years to build the capabilities that XNRGI already has today. With XNRGI, battery production can be scaled immediately to the cost level needed to meet emerging market demand and ultimately replace fossil fuel energy.

"With the advent of cheap battery storage, it is becoming increasingly possible to refine the supply of wind and solar power, so that these technologies can help meet demand even when the wind is not blowing and the sun is not shining. The result will be renewable energy, which is increasingly replacing the existing market for coal, gas and nuclear power. "Bloomberg NEO 2018 ″

XNRGI: A new battery architecture

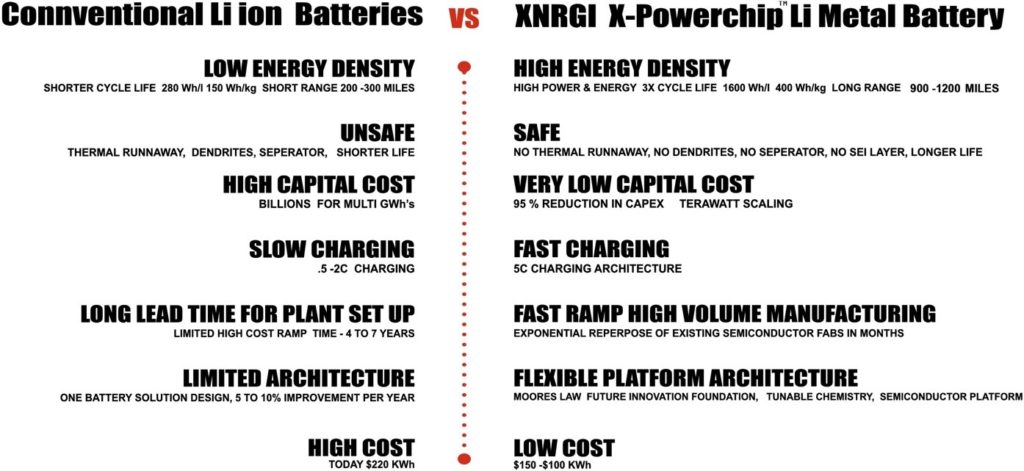

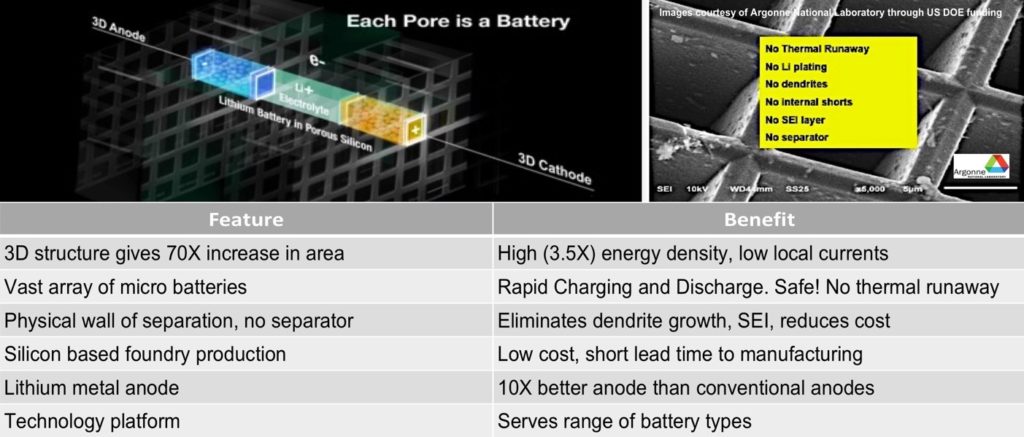

XNRGI, recently funded by the US Department of Energy (DOE) for the prefabrication of the X-PowerChip ™, has developed a groundbreaking, high-capacity, rechargeable lithium metal battery (using a 3D porous silicon structure as the electrode substrate) that can be fabricated with an inexpensive, contract-based semiconductor foundry model to reduce CapEx costs by 95% (compared to traditional battery factories, which take billions and years of construction to build). Most importantly, the semiconductor manufacturing of the XNRGI battery allows the technology to improve in the same way as semiconductor improvements (i.e. Moore's Law) as lithium-ion technology approaches its limited potential for improvement.

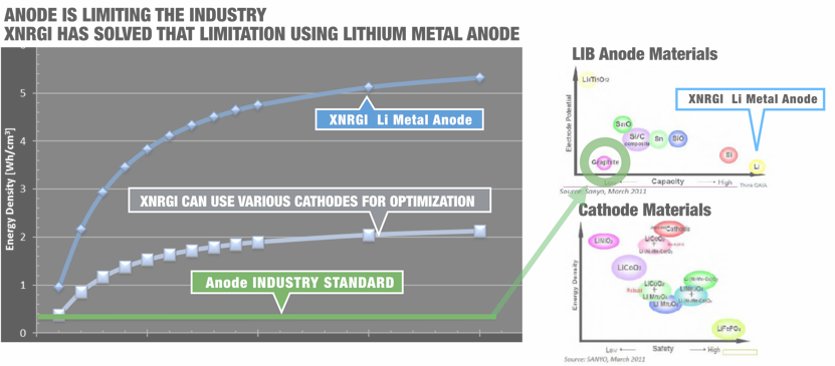

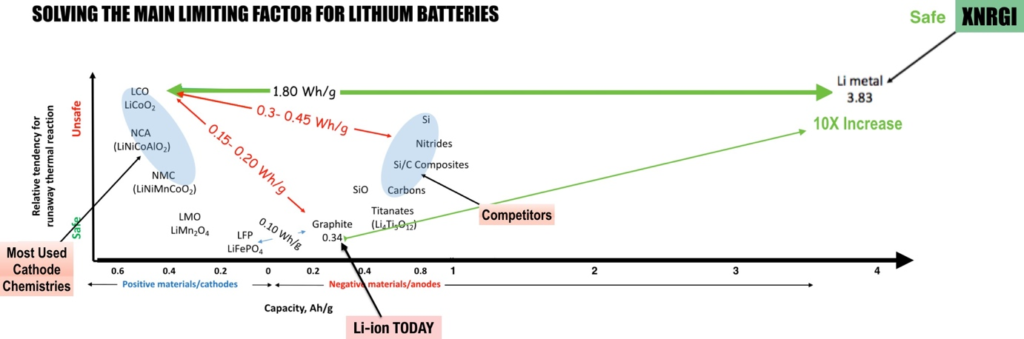

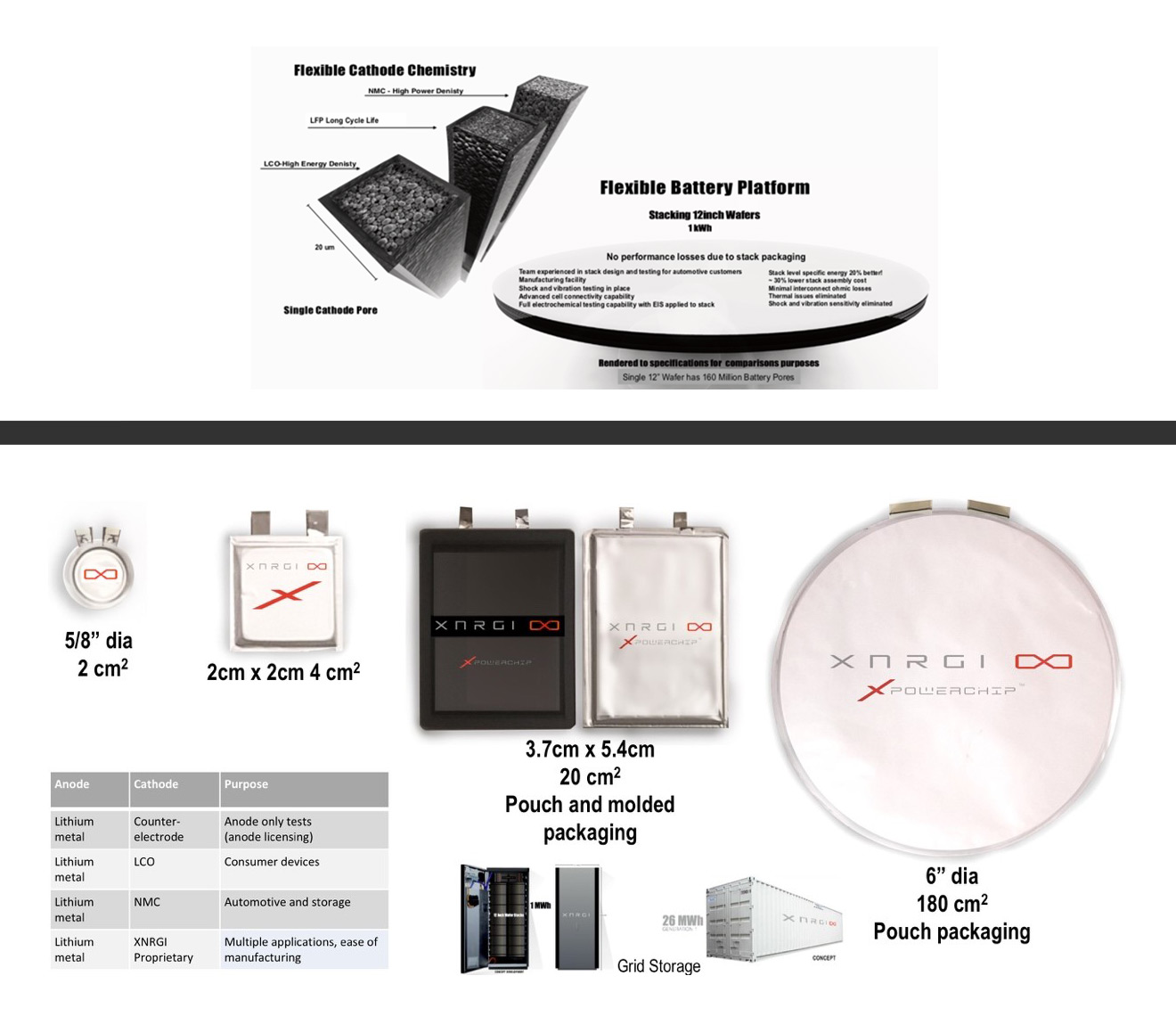

The XNRGI technology platform is based on the most versatile manufacturing platform the battery industry has seen in its long history. It has addressed numerous disadvantages of the old conventional battery technology that has plagued the battery industry for the past 30 years. XNRGI's lithium metal anode has ten times the energy density of a standard lithium-ion anode. When combined with XNRGI's 3D pores, which increase the battery's active surface area by 70 times, it improves performance significantly. At the same time, XNRGI's 3D pores create a cool and safe architecture for any battery chemistry, essentially eliminating the overheating and fire concerns that plagued other lithium-ion batteries. The XNRGI battery design is chemically agnostic in that it does not limit the use of almost any cathode material, including the most common LCO, NMC, NCA, or LFP cathode materials. The main advantages of this method are: High energy density - lithium metal battery with (> 1600 Wh / L) 400 Wh / kg and lithium metal-air with (4400 Wh / L) 680 Wh / kg, with high currents that a enable rapid charging and discharging, a long service life based on the elimination of lithium dendrite formation, greatly improved safety and inexpensive series production. XNRGI's 3D architecture provides a safe environment for chemicals that will be used in large quantities for future high energy density innovations and that can be safely stored.

Product roadmap for performance / price

XNRGI has produced 1000 Work Samples (10 billion microbatteries) for a wide range of customers and has demonstrated that it is capable of producing batteries regardless of application or scale at a price of less than 150 USD / kWh.

Technological advantages:

XNRGI believes that their silicon architecture offers several benefits in terms of performance, cost, manufacturability, and technology expandability, including optimization of packaging, safety, performance, and energy density. An application for a range of different sizes from micro batteries to large batteries (for installation in electric vehicles and in Superconducting Magnetic Energy Storage (SMES)). XNRGI also offers the ability to make improvements to the battery every 18 to 24 months; In contrast to conventional battery architectures, continuous improvements are possible.

XNRGI is the ONLY flexible architecture platform that enables high-performance, low-cost mass production of batteries that enables the mass deployment of electric vehicles and renewable energy.

XNRGI's proprietary PowerChip ™ battery

In addition to XNRGI's IP portfolio with 15 issued patents, 13 applications and 6 patent applications, XNRGI's PowerChip ™ technology has a number of unparalleled, unique features that set it apart from all other battery technologies:

Competition of XNRGI

XNRGI covers all five main features:

- energy density

- Safety

- cost-effective, capital-efficient production

- flexible technology platform (unlimited applications)

- short lead time for manufacturing to win a new, mass-produced supplier (usually 3-6 months).

Conversely, competitors usually meet only one or two of the five main areas of battery performance (energy density and / or safety). They are burdened with the high capital costs associated with long lead times for manufacturing, and are limited to one cathode, and thus one type of application.

Benefits of Scalable and Optimizable Market Application of XNRGI

The benefits of the scalable and optimizable application of XNRGI during the Early Adopter Program (EAP) have been delivered to more than 600 Work Samples (8 billion microbatteries) for a wide range of customers. Now, the company is looking for high-volume launch partners to leverage the unique storage applications of the new technology.

Early adopter programs have demonstrated the effectiveness of XNRGI technologies in several areas, including:

- Grid scale storage for intermittent renewable energy such as solar / wind and backup power

- Electric vehicles with 3-6 power density and 2-3 lighter weight reduction at significantly lower cost.

- Consumer electronics: Highest watt-hours per liter at 1600 Wh / l for long-lasting performance.

- Internet of Things with a high performance in micrometer size and the benefits of a slow discharge.

Summary

Driven by mobility and network-based storage, the global battery market will grow at an annual rate of more than 40% over the next few years.

XNRGI is uniquely positioned to address the industry-wide challenges of performance, cost, security, outsourced manufacturing and short lead time to manufacturing. The architecture serves as an innovation platform that will enable an evolutionary path for the advancement of the battery in the coming years.

XNRGI has significant advances and early adopter programs with the world's largest manufacturers of computing, grid, consumer electronics and IoT products and is equally well positioned to deliver rapid, profitable growth and global demand for electric energy storage cover.

Source: Text and images XNRGI Translation: Institute for Rare Earths and Metals - July 2019